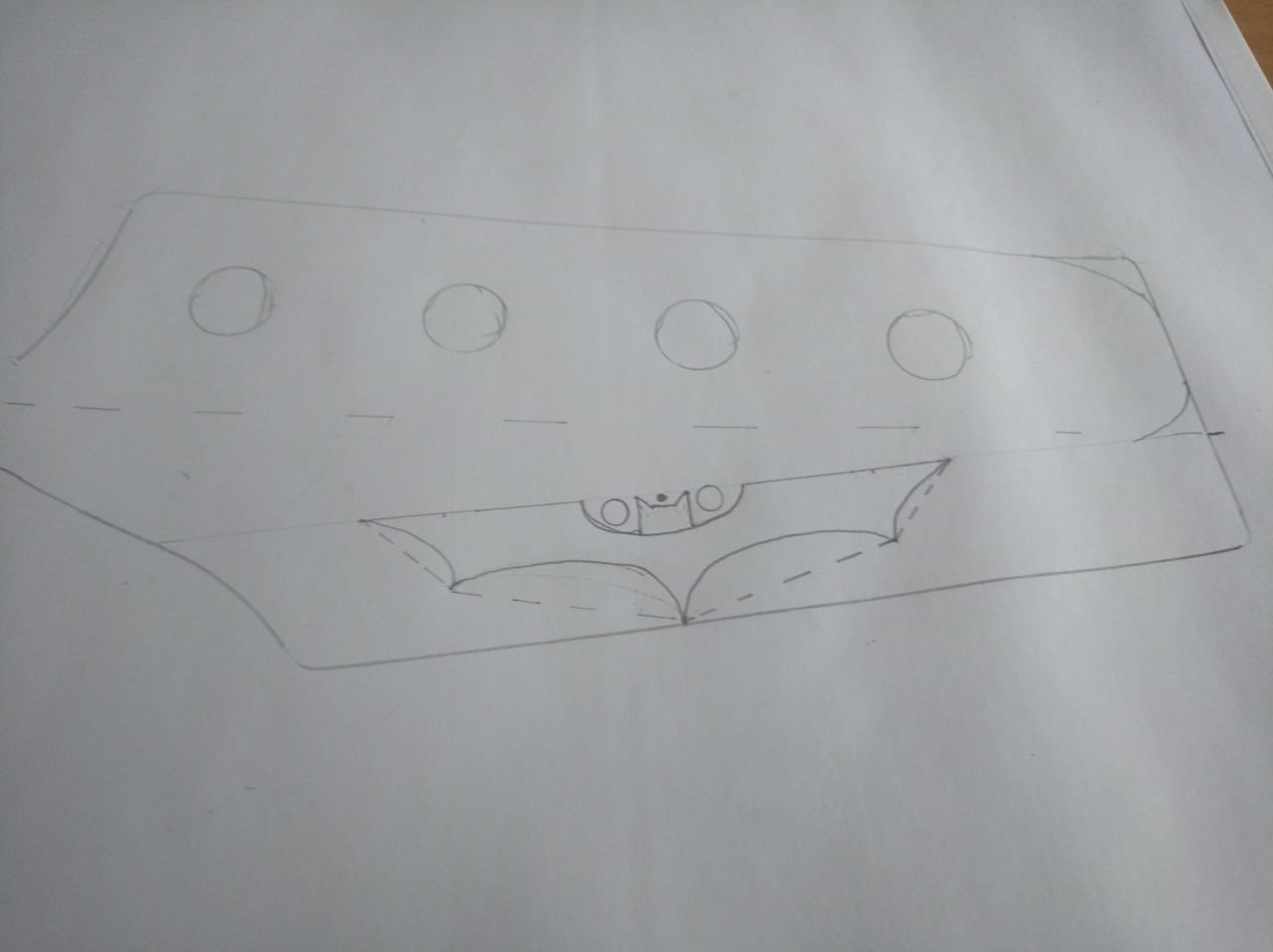

So since it seems to me my caped bassist premiere was generally well received I had this idea:

I tried it without the head of the logo but that just doesn’t look right. I think I’ll try my best and still have a failsave of just removing the batman logo alltogether and just have a headstock with a rounded end.