I spoke to him very briefly earlier in the year (last year, obviously) about putting word out about all his gear for sale. Unfortunately, I have very few contacts in the music world who live within 500 miles, and he’s too distracted with his new baby to put any time into doing anything with it. I could probably push the matter along by speaking with his mum and convincing her that she needs the space back, but there are some lines you shouldn’t cross - going to somebody’s mum behind their back is one of them. ![]()

Leaving this here for posterity for those getting serious with project basses:

https://www.sweetwater.com/store/detail/ToneCapsule--darkglass-tone-capsule-bass-preamp-system

Onboard Darkglass preamp. What differentiates it from the other high end ones like Aguilar or Sadowsky is that its 3-band EQ is bass/low mids/high mids, with no treble control.

Coming along nicely, @terb! What are these marks on the back of the headstock??

remember that it’s an old and crappy bass, it’s full of hits and scratches

Nice @terb! Any particular brand? 11/16” or 23/32”? I believe Fender typically uses 11/16” but the holes can be reamed for the larger bushings…

I don’t know, here we use the metric system  it’s about 18mm for the insert (I drilled to 17mm and adjusted by hand). The tuning machines are cheap chinese ones, its a low budget project !

it’s about 18mm for the insert (I drilled to 17mm and adjusted by hand). The tuning machines are cheap chinese ones, its a low budget project !

Yeah, part of the fun of ordering parts is figuring out if it’s US or metric, or just getting “close enough”, and making it work!

I ordered pretty cheap parts off of Amazon for that project bass I did a few months ago, and many of them shipped from China. As in, they apparently had to clear customs from the shipping tags, and came directly from a factory there. But they were really decent quality for the very low price, only trade-off was that it took 3 weeks to a month for them to arrive!

How are you liking the bass you did?

Well, it’s a neat showpiece, and I’m satisfied at completing the project. But, playing it, there’s just something that doesn’t feel that great about it, to be honest! A bass made to certain specs in a factory just sort of feels more reliable, I guess. Or maybe a high-end custom one made by an experienced luthier.

Could be psychological. I know in the past I have been super critical of my own DIY work compared to others when in fact the issue was mostly that I likely “knew” all the issues with it (since I made it) rather than not having seen the issues along the way in the other people’s stuff I was using

@Vik Are you planning to put more time/money into it or are you calling it done for a first DIY bass project? Is there any more you were hoping to learn?

@howard I definitely suffer from this. Sometimes ignorance really is bliss. Knowing all the flaws makes it really difficult for me to know when to just call it “done” and move on to another project.

I’ve experienced that myself after working on my car or motorbike - especially after working on the bike’s brakes. Take it to a mechanic and I won’t think twice about the job, but let e at it and I’ll forever be hearing noises etc. Same applies to anything I make: I know the flaws or problems I overcame, and they will always be obvious to me.

Hehe… after my first string change, I was all but wearing a safety helmet, and constantly afraid that the strings might pop off violently at any time

Nobody else has ever been like that, @joergkutter.

I had just bought my 604 and changed the strings, and apparently I failed to seat one of the strings in the saddle notch. So I did a setup with the new strings, adjusted the truss rod a bit, and was about to work on the action when the bass went SNAP as the string snapped into position on its own. Only I didn’t figure that out right away and started swearing because I assumed I had snapped the truss rod

I think for a first project, it’s done! But I’m just not in that phase anymore, where I want to take a bass apart, and put it back together, I feel like that one project was a great fix for that, and the learning was worth the confidence gained for making simple mods, or repairs. The bass wasn’t the best quality one in the first place, the wood is just too heavy, and I can feel the small differences in quality now (hopefully more a connoisseur, not a snob!); so the finished product, no matter what, I just don’t feel the musical connection with it.

Probably some truth to that! And the fact that the work I put into it was so lacking in so many ways ![]()

This makes all the sense in the world @Vik … Can fully understand and relate where you’re coming from here…

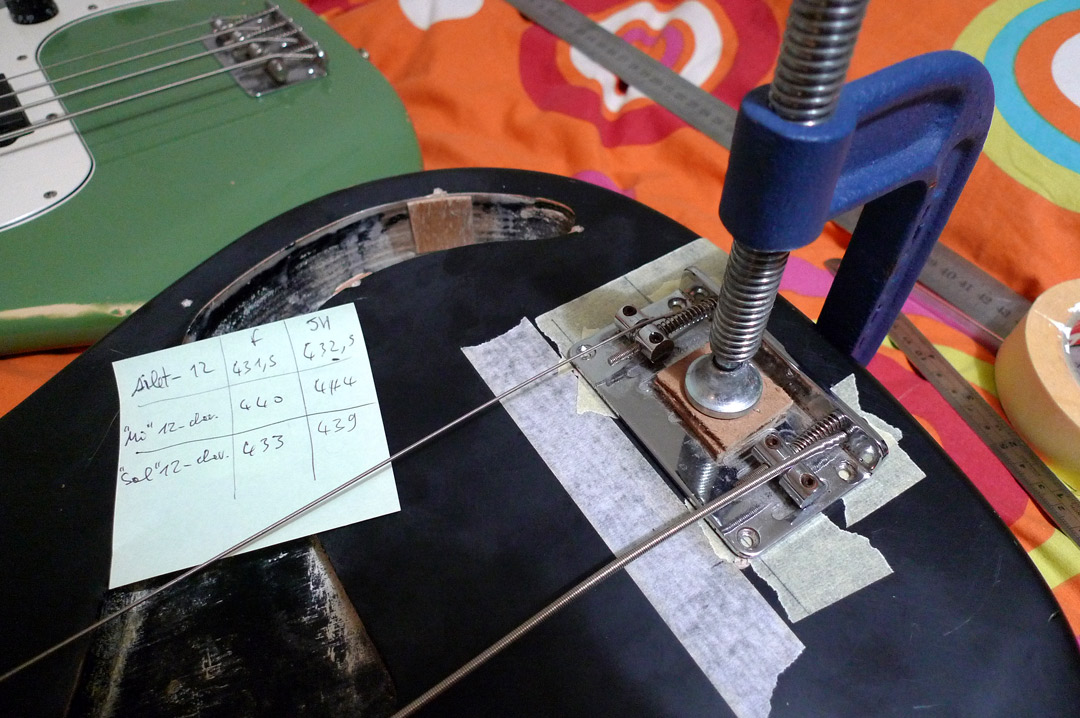

some news about the Jim Harley Precision … I’m currently re-locating the bridge, which was not aligned with the neck (yes …). Greenie as a measuring example + some calculation and masking tape involved !

Did you just proactively decide to double check its alignment or did it look and/or feel off that led you down that path?