The original headless bass mod has been stalled for a while. It’s never had proper pickups put in it.

Cheap-ass Ebay specials from China proved the concept was workable, but didn’t fit the routed out holes in the body particularly well, and wasn’t a specific enough sound.

So what’s next?

I need to find exactly the right size pickups, that make a sound that I like, and will work with the electronics that I already have.

And not cost a bajillion dollars. I’ll never get the money back on this bass.

What are the chances of that?

They’re not good.

Verging on incredibly remote.

The only things I’ve ever liked are the Nordstrand pickups on the 2021 Ibanez SR600.

At least that has the same electronics as the headless.

They sounded pretty damn good.

I’ve never checked the Nordstrand size though, because there’s no point.

They’re quite expensive and they’re not going to turn up second hand.

Until they turned up second hand on facebook marketplace on the 14th of July.

WTF?

Well, they won’t fit anyway.

That kind of coincidence never happens.

Except the Nordstrand website says that they are exactly the right size….

And the seller just cut the price down from extremely reasonable to very cheap, and threw in a Nordstrand 3b EQ and the entire wiring hardness, with an extra push/pull pot

And he’s posting it for free.

So I bought them.

Throwing them in was a matter of a few minutes… which is good because this project has been going for hmm… 2 years, 5 months and 29 days to get to this point.

We shouldn’t rush these things

The bad news: The three position switches which let me switch coil windings from series, single and parallel on the Cheap Chinesium Pickups of Doom, now only do single and parallel on the Nordy’s.

The last switch position, like Radioactive Man’s goggles, do nothing.

The good news: This thing is now VERY versatile.

Our local bass god gives it a quick test thrash in the video below.

Total mods include:

2004 Ibanez BTB400SQM

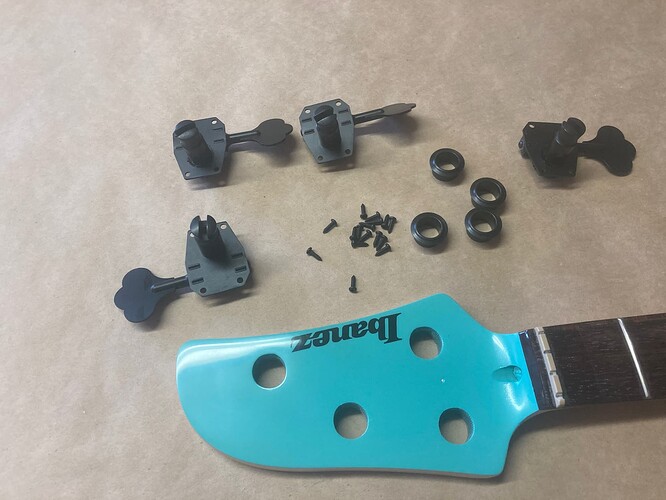

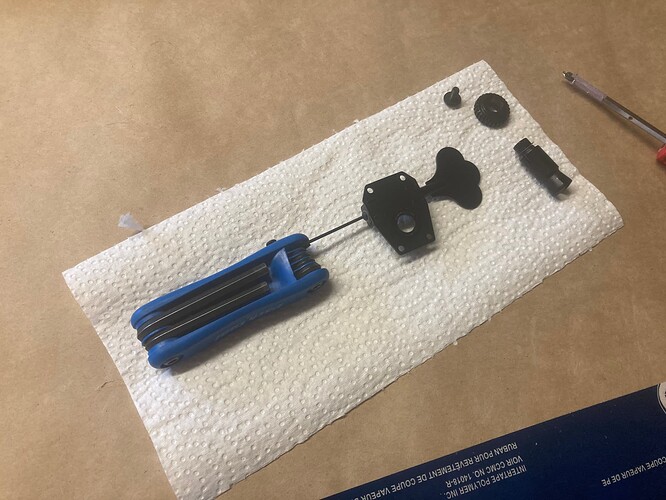

Converted to headless.

Painted black.

Completely shielded in solder joined copper tape - even the tunnels to the pickups. (because I was bored and it was fun to do:

Hatch cover screws are now machine screws into threaded brass inserts.

Converted to current Ibanez EQ.

Stacked knobs for Volume/Mix, Bass/Treble, Mids/Sweep. (All standard Ibanez parts)

Nordstrand Fat Stacks pickup switchable between Humbucker/Single

Locking jack de-locked.

Twin strap studs on the bottom (or it leans to one side…)

The only thing left to do is level and crown the frets and maybe go to the newest method of adjusting strings on the Novus bridge… which will just require some more money…